1. High Mechanical Strength

Designed with robust construction to withstand electrodynamic forces and cable tensile forces during circuit breaker operation. Resists deformation or damage under stress, ensuring long-term reliability.

2. Easy Installation

Optimized structural design enables seamless integration. Standardized specifications and interfaces allow rapid and precise connections to circuit breakers and conductors, significantly improving installation efficiency.

3. High-Temperature Resistance

Capable of withstanding elevated temperatures generated during normal operation or overload conditions. Prevents softening or deformation to maintain stable connection integrity and electrical performance.

1. Excellent Conductivity

Constructed from high-purity copper, these terminals exhibit low electrical resistance for efficient current transmission. This minimizes heat generation and power loss, ensuring reliable performance of the circuit breaker under rated loads.

2. Secure Connection

Engineered with precision-fit interfaces, the terminals form tight connections with both circuit breakers and conductors. This design prevents loosening caused by vibration, thermal cycling, or current surges, guaranteeing long-term circuit integrity.

3. Superior Corrosion Resistance

Copper’s inherent corrosion resistance enables stable operation in humid, chemically aggressive, or high-salinity environments. Resists oxidation and sulfidation, effectively extending service life and reducing maintenance requirements.

1. Electrical Connectivity

Establishes a secure electrical connection between the circuit breaker and conductors, enabling smooth current transmission within the circuit.

2. Current Distribution

Evenly distributes conductor current across multiple contacts of the circuit breaker. Prevents localized current concentration, ensuring balanced thermal and electrical performance across all components.

3. Maintenance-Friendly Design

Facilitates easy disassembly and reconnection of conductors during circuit breaker maintenance or replacement. Protects conductor insulation and terminal interfaces from damage, streamlining troubleshooting and repair workflows.

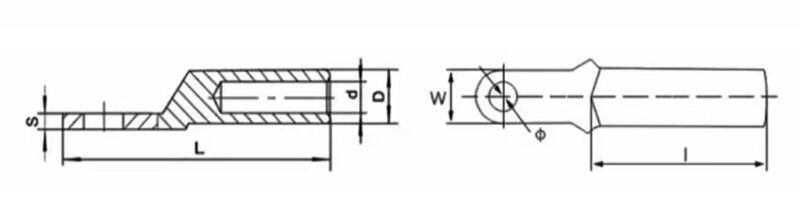

| Model | Screw hole diameter(mm) | Product size(mm) | Wire cross-section(mm) | |||||

| L | 1 | D | d | S | W | |||

| DT-35 | 8.5 | 78 | 37 | 12 | 8.8 | 2.8 | 16 | 35 |

| DT-50 | 8.5 | 79 | 40 | 13.2 | 9.8 | 3.4 | 16 | 50 |

| DT-70 | 8.5 | 84 | 42 | 15.2 | 11.4 | 3.6 | 16 | 70 |

| DT-95 | 8.5 | 90 | 46 | 17 | 13 | 3.9 | 16 | 95 |

| DT-120 | 8.5 | 93 | 52 | 19 | 15 | 4.8 | 16 | 120 |

| DT-150 | 8.5 | 105 | 53 | 21 | 17 | 4.4 | 16 | 150 |

| DT-185 | 8.5 | 110 | 53 | 24.2 | 18.6 | 5 | 16 | 185 |

| DT-240 | 8.5 | 118 | 60 | 26 | 21 | 6.2 | 16 | 240 |

Our professional sales team are waiting for your consultation.