1. Rational Structural Design

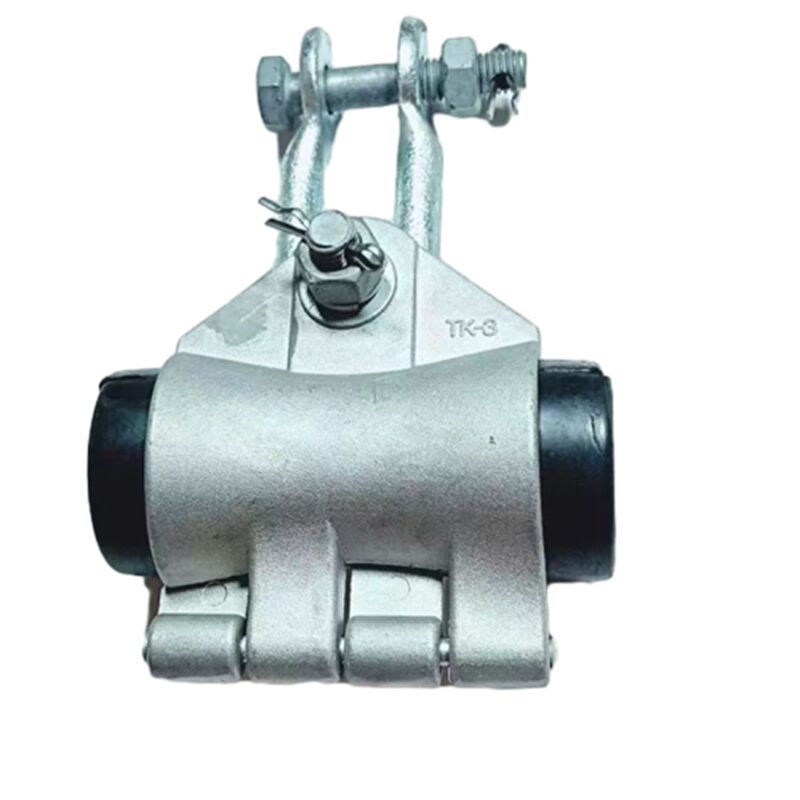

Typically composed of inner strands, outer strands, rubber clamping blocks, and suspension plates. The inner and outer strands adopt a preformed strand structure, which evenly distributes the stress on the optical fiber cable, while the rubber clamping blocks protect the cable and increase friction. This multi-component design ensures both mechanical stability and cable protection, with the preformed strands conforming to the cable’s curvature to prevent localized stress concentrations.

2. High-Quality Materials

Outer Strands: Usually made of high-strength aluminum alloy or stainless steel, featuring lightweight, corrosion resistance, and high strength. These materials withstand outdoor environments while minimizing the clamp’s overall weight for easier installation.

Inner Strands: Commonly constructed from aluminum alloy or zinc alloy, with smooth surfaces that closely fit the cable to avoid damage. The metallic structure provides reliable mechanical support while maintaining flexibility.

Rubber Clamping Blocks: Made of aging-resistant and wear-resistant rubber materials, they offer excellent protection for the optical fiber cable, cushioning mechanical shocks and preventing abrasion during wind-induced vibrations or temperature changes.

3. Strong Grip Force

Through the special design of preformed strands and the coordination of rubber clamping blocks, the clamp provides significant grip force, ensuring firm clamping of the optical fiber cable under various environmental conditions. The preformed strands’ helical structure wraps tightly around the cable, while the rubber blocks enhance friction, preventing slippage and ensuring the cable remains securely suspended in all operational scenarios.

E-mail:

E-mail: