1. High Strength

Typically made of high-quality alloy steel through forging and heat treatment processes, they can withstand significant tensile forces. For example, the common QP-16 type ball head suspension clamp has a nominal breaking load of up to 160 kN, meeting the mechanical requirements of transmission lines. The alloy steel material and precise manufacturing ensure reliable performance under long-term heavy loads, suitable for high-voltage and ultra-high voltage overhead systems.

2. Good Toughness

When subjected to tensile or impact forces, they can absorb energy through self-deformation, making them less prone to brittle fracture and improving the reliability of transmission lines. This ductile property is critical for resisting sudden loads. preventing catastrophic failures that could lead to line outages. The combination of strength and toughness ensures stable operation in dynamic environments.

1. Convenient Connection

The ball head fits into the bowl head of the insulator, while the shank is connected to other fittings via bolts, enabling easy installation and disassembly and improving construction efficiency. This quick-fit design reduces high-altitude operation time, especially advantageous for large-scale stringing projects or maintenance work requiring frequent component replacement.

2. Strong Versatility

Available in various specifications and models, it can connect with different types and sizes of insulators and other fittings Its standardized interface design complies with international standards. ensuring compatibility in global power projects.

3. High Stability

With a secure and stable connection, it maintains reliable performance during long-term operation, minimizing line faults caused by loose connections. The precision-forged ball-and-socket joint design eliminates play, while anti-loosening bolts further enhance vibration resistance. This stability is critical for high-wind areas or long-span lines, where unstable connections could lead to conductor sag or fitting failure.

1. Connection Realization

It connects insulators with fittings such as suspension clamps and strain clamps, forming a complete suspension or fixing system for transmission lines. This modular connection ensures the mechanical integrity of the overhead line, enabling reliable integration of insulating components and mechanical load-bearing components.

2. Load Transmission

During transmission line operation, it transmits the gravitational force, tension, and wind load of the conductor to the utility poles or towers, ensuring the mechanical balance of the line. The clamp’s robust structure efficiently distributes dynamic and static loads, preventing stress concentrations that could lead to component failure.

3. Adaptation to Line Movements

When the conductor displaces due to thermal expansion/contraction, wind galloping, or other factors, the ball head suspension clamp’s articulating joint allows insulators and fittings to adapt to such movements, avoiding additional stress damage to the line. This flexibility is critical for maintaining electrical clearances and mechanical stability in dynamic environments, such as long-distance transmission lines crossing thermal expansion zones or high-wind regions.

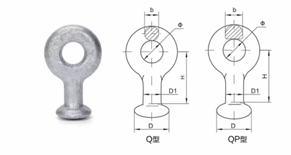

| Model | Size(mm) | Load(KN) | Weight(kg) | ||||

| Φ | b | H | D | D1 | |||

| Q-7 | 22 | 16 | 50 | 33.2 | 17 | 70 | 0.3 |

| QP-7 | 20 | 16 | 50 | 33.2 | 17 | 70 | 0.3 |

| QP-10 | 20 | 16 | 50 | 33.2 | 17 | 100 | 0.3 |

| QP-12 | 24 | 16 | 50 | 33.2 | 17 | 100 | 0.3 |

| The data is manually measured and for reference only,Please refer to the actual product. | |||||||

Our professional sales team are waiting for your consultation.