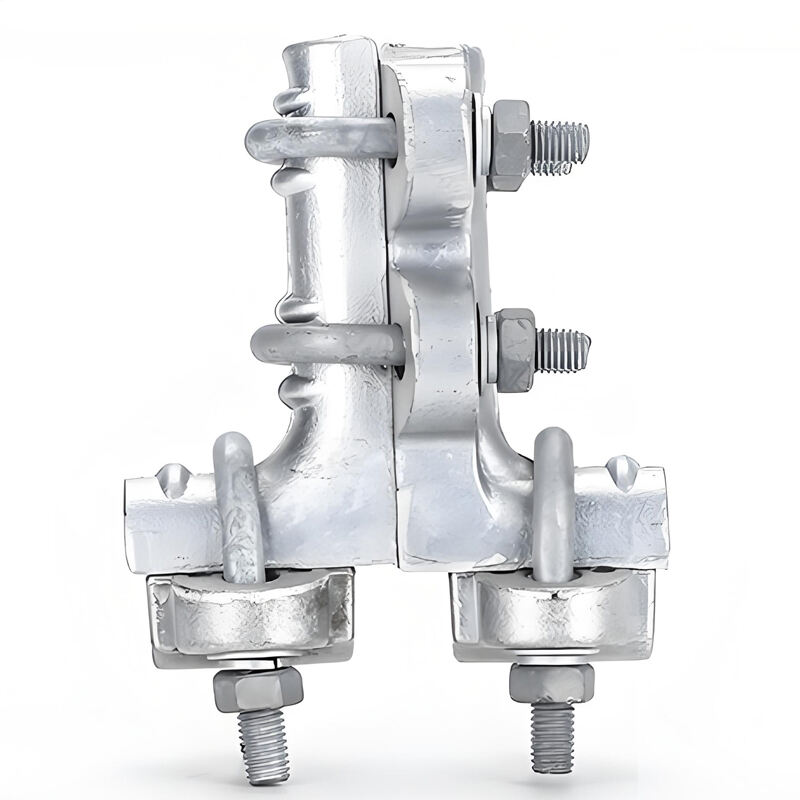

1. Reasonable Structural Design

Composed of a T-shaped base body, main line groove cover, T-shaped upper cover, etc. The horizontal part of the base body is provided with a main line groove, and the vertical part is provided with a branch line hole. The inner wall is equipped with a metal lining that is integrated, and the conductor connection is realized through compression screws.

2. High-Quality Materials

Usually made of materials consistent with the wrapped stranded wires, such as copper or aluminum, with strong corrosion resistance.

3. Good Electrical Performance

The branch conductor and main conductor are in close contact with the metal lining through compression screws, with a large contact area. The DC resistance is not greater than that of an equal-length conductor, and the current-carrying temperature rise is lower than that of the conductor. No visible corona occurs under 1.05 times the operating voltage (when the operating voltage is 330KV and above).

4. Stable Grip Strength

The grip strength on the conductor is not less than 10% of the conductor's calculated breaking force. For bolt-type clamps applicable to conductors with a diameter greater than 49mm, the grip strength is not less than 3%.

E-mail:

E-mail: