MDG-001-3

1. Vật liệu độ bền cao

Thường được làm từ hợp kim nhôm chất lượng cao hoặc thép độ bền cao, có độ bền và độ cứng lớn. Chúng có thể chịu được trọng lực và lực kéo của thanh cái, cũng như các lực điện động phát sinh trong trường hợp ngắn mạch, đảm bảo cố định chắc chắn thanh cái.

2. Dẫn điện tốt

Các vật liệu như hợp kim nhôm mang lại khả năng dẫn điện tuyệt vời, giảm tổn thất điện tại các điểm nối phụ kiện và ngăn ngừa suy giảm hiệu suất phụ kiện do phát nhiệt.

3. Chống ăn mòn

Bề mặt được xử lý chống ăn mòn bằng các biện pháp như mạ kẽm, mạ niken hoặc phủ lớp chống ăn mòn, mang lại khả năng chống chịu ăn mòn cao. Điều này giúp các phụ kiện này thích nghi với nhiều môi trường ngoài trời khác nhau và kéo dài tuổi thọ sử dụng.

4.Cấu trúc gọn nhẹ

Với thiết kế gọn nhẹ, chúng chiếm ít không gian, tận dụng hiệu quả không gian lắp đặt thanh cái đồng thời thuận tiện cho việc lắp đặt và bảo trì.

1.Lắp đặt thuận tiện

Nhờ thiết kế cấu trúc hợp lý, việc lắp đặt không đòi hỏi các công cụ phức tạp hay quy trình đặc biệt. Các thanh cái có thể được cố định nhanh chóng, nâng cao hiệu suất thi công.

2. Độ tin cậy cao

Có thể cố định thanh cái một cách đáng tin cậy, ngăn ngừa sự dịch chuyển, rung lắc hay rơi ra của thanh cái trong quá trình vận hành, đảm bảo hệ thống điện hoạt động an toàn và ổn định.

3. Tính linh hoạt cao

Có sẵn nhiều thông số kỹ thuật và kiểu dáng khác nhau, phù hợp với nhiều loại và tiết diện thanh cái khác nhau, bao gồm thanh cái đồng và thanh cái nhôm, mang lại tính linh hoạt cao.

4. Chi phí bảo trì thấp

Nhờ vật liệu chất lượng cao và khả năng chống ăn mòn, việc bảo trì thường xuyên là không cần thiết trong điều kiện hoạt động bình thường, giúp giảm chi phí bảo trì.

1. Cố định thanh cái

Chức năng chính là cố định chắc chắn thanh cái trên các cách điện đỡ hoặc giá đỡ thanh cái, giữ thanh cái ở vị trí và khoảng cách quy định để đáp ứng yêu cầu lắp đặt và vận hành của thiết bị điện.

2. Dẫn điện

Trong khi cố định thanh cái, nó có thể dẫn dòng điện trong thanh cái một cách hiệu quả, đảm bảo truyền tải điện năng ổn định, giảm điện trở tiếp xúc và hạn chế phát nhiệt.

3. Chịu tải

Nó chịu được các tải tự nhiên như trọng lượng bản thân thanh cái, sức gió, băng tuyết, cũng như lực điện động lớn sinh ra trong trường hợp ngắn mạch, đảm bảo sự ổn định của hệ thống thanh cái trong mọi điều kiện làm việc.

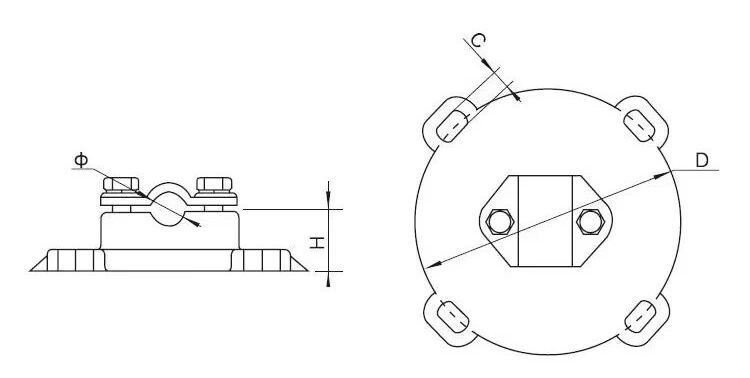

| Mô hình | Tiết diện dây dẫn(mm) | Kích thước | |||

| φ | H | C | S | ||

| MDG-2 | 70-95 | 14 | 25 | 14 | 140 |

| MDG-3 | 120-150 | 17 | 30 | 14 | 140 |

| MDG-4 | 185-240 | 22 | 30 | 14 | 140 |

| MDG-5 | 300-400 | 28 | 33 | 14 | 140 |

| MDG-6 | 500-630 | 34 | 36 | 14 | 140 |

| MDG-2-225 | 70-95 | 14 | 25 | 18 | 225 |

| MDG-3-225 | 120-150 | 17 | 30 | 18 | 225 |

| MDG-4-225 | 185-240 | 22 | 30 | 18 | 225 |

| MDG-5-225 | 300-400 | 28 | 33 | 18 | 225 |

| MDG-6-225 | 500-630 | 34 | 36 | 18 | 225 |

| MDG-2-250 | 70-95 | 14 | 25 | 18 | 250 |

| MDG-3-250 | 120-150 | 17 | 30 | 18 | 250 |

| MDG-4-250 | 185-240 | 22 | 30 | 18 | 250 |

| MDG-5-250 | 300~400 | 28 | 33 | 18 | 250 |

| MDG-6-250 | 500-630 | 34 | 36 | 18 | 250 |

| Tất cả các kích thước được cung cấp đều đo thủ công và có thể chứa sai số nhỏ. Kích thước cuối cùng sẽ căn cứ theo sản phẩm thực tế | |||||

Đội ngũ bán hàng chuyên nghiệp của chúng tôi đang chờ đợi cuộc tư vấn của bạn.

Bản quyền © Công ty TNHH Thương mại Quốc tế GuangZhou XinChuang LianRui. Mọi quyền được bảo lưu. - Chính sách bảo mật- Không.Blog