JBT-001-3

Matériau en cuivre pur et haute conductivité électrique :

Il est fabriqué en cuivre rouge de haute qualité T3 ou en cuivre rouge épaissi T2, avec une pureté de plus de 99,9 %, garantissant que l'efficacité de transmission du courant est augmentée de plus de 30 % par rapport aux pinces de base en aluminium. La haute conductivité électrique du cuivre (avec une résistivité d'environ 0,017Ω·mm²/m) réduit efficacement les pertes sur la ligne, ce qui le rend particulièrement adapté aux scénarios de courant à haute fréquence ou à fort courant.

Structure d'engrenage dentelé et de serrage en arc :

La conception interne en saillie dentelée peut percer la couche d'oxyde présente à la surface du fil, formant un contact métallique direct. La surface de contact est supérieure de 40 % par rapport à celle des pinces ordinaires pour fils. En combinaison avec la structure de serrage en surface en forme d'arc, en appliquant une pression uniforme à plusieurs points, le fil peut maintenir une performance de fluage stable sous des variations de température allant de -30℃ à 90℃.

Composants intégrés et traitements anti-corrosion :

Le corps principal du serre-câble et la plaque de pression sont fabriqués par un procédé d'injection intégrale, évitant ainsi le problème de détachement facile des pièces dans le design divisé. Les boulons et les parties métalliques ont tous subi un traitement de galvanisation à chaud. Les tests de projection saline montrent que sa résistance à la corrosion est deux fois meilleure que celle du processus ordinaire de nickelage, ce qui le rend adapté aux environnements humides ou pollués industriellement.

Adaptation multi-spécifications et conception normalisée :

Nous proposons différents modèles allant de JBT-0 à JBT-4, compatibles avec des fils tressés en cuivre ou des câbles à cœur en cuivre allant de 16 à 240mm². La hauteur du serre-câble est ajustable (par exemple, la hauteur du type JBT-44 peut atteindre 108mm), permettant la connexion de conducteurs de même diamètre ou de diamètres différents, répondant ainsi aux diverses exigences des lignes aériennes de 10kV et moins.

Conductivité électrique excellente :

Le matériau en cuivre rouge a une excellente conductivité électrique. Couplé à une résistance de contact relativement faible, il peut réduire significativement les pertes lors du transfert d'énergie électrique, diminuer la génération de chaleur et améliorer l'efficacité du transfert de puissance.

Installation facile :

La méthode d'installation est simple, aucun outil spécial n'est nécessaire, ce qui permet de réduire le temps d'installation et les coûts de main-d'œuvre tout en augmentant l'efficacité du chantier.

Bonne performance de protection :

Il peut être utilisé avec un couvercle isolant pour empêcher la poussière et les projections d'eau, protégeant efficacement l'isolation et améliorant la sécurité opérationnelle de l'étau à fils dans des environnements difficiles.

Forte résistance à la corrosion :

Le matériau en cuivre est moins sujet à la corrosion électrochimique. Comparé à la connexion cuivre-aluminium, il est plus adapté pour une utilisation à long terme dans divers environnements et offre une durée de vie plus longue.

Connexion filaire : Elle est principalement utilisée pour la connexion et le branchement non porteurs de fils en cuivre dans les lignes électriques aériennes, et peut également être utilisée pour la connexion de saut entre les pylônes non linéaires. Elle permet d'obtenir une connexion fiable entre deux fils en cuivre de même spécification ou de spécifications différentes.

Transmission électrique : En tant que matériel électrique, elle peut garantir que le courant passe sans problème aux points de connexion des conducteurs, assurer la transmission normale de l'énergie et maintenir le fonctionnement stable des lignes.

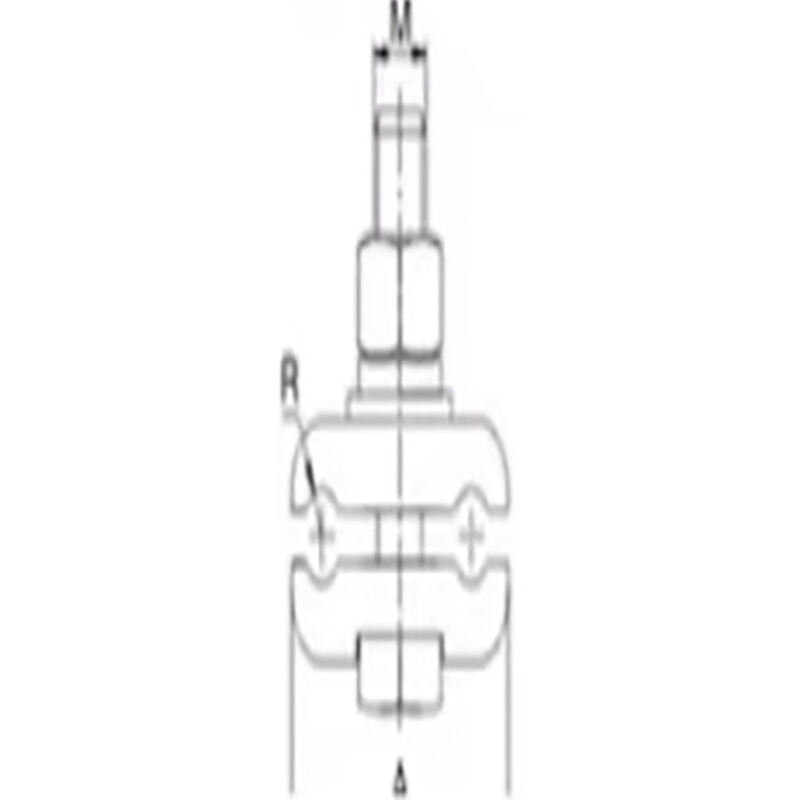

| Modèle | Surface du conducteur (mm) | Quantité | TOUTES DIMENSIONS (MM) | |||

| R | A | 1 | M | |||

| JBT-0 | 16-25 | 2 | 4.0 | 35 | 55 | 10 |

| JBT-1 | 35-50 | 2 | 5.0 | 40 | 60 | 10 |

| JBT-2 | 70-95 | 3 | 7.0 | 50 | 90 | 12 |

| JBT-3 | 120-150 | 3 | 8.5 | 63 | 108 | 12 |

| JBT-4 | 185-240 | 3 | 10.5 | 65 | 108 | 12 |

| Toutes les mesures fournies sont obtenues manuellement et peuvent contenir de légères tolérances. Les dimensions finales seront soumises au produit physique. | ||||||

Notre équipe de vente professionnelle attend votre consultation.

Droits d'auteur © GuangZhou XinChuang LianRui International Trade Co., Ltd. Tous droits réservés. - Politique de confidentialité-Blog