1.עמידות גבוהה לאירוזיה

המשטח מטופל בשיטות טבילה חמה, אשר יכול למנוע באופן יעיל חלודה . קורוזיה זה מתאים לסביבות מורכבות כמו חוץ . נמלים, מאריך את משך החיים.

2.תפוצה רחבה

ניתן להשתמש בו ביישומים שונים של הרמה . תואם לציוד הרמה רב-גוני כמו מנחות. שרשרות. מיושם בתעשייה, ספינות, אתרים בנייה . תרחישים אחרים.

1. עוצמה אמינה

ייצור מפליז פליז באיכות גבוהה, עם חוזק מתיחה, חוזק נטיה וקשיחות גבוהים, כדי למנוע שבירה עקב עומס יתר

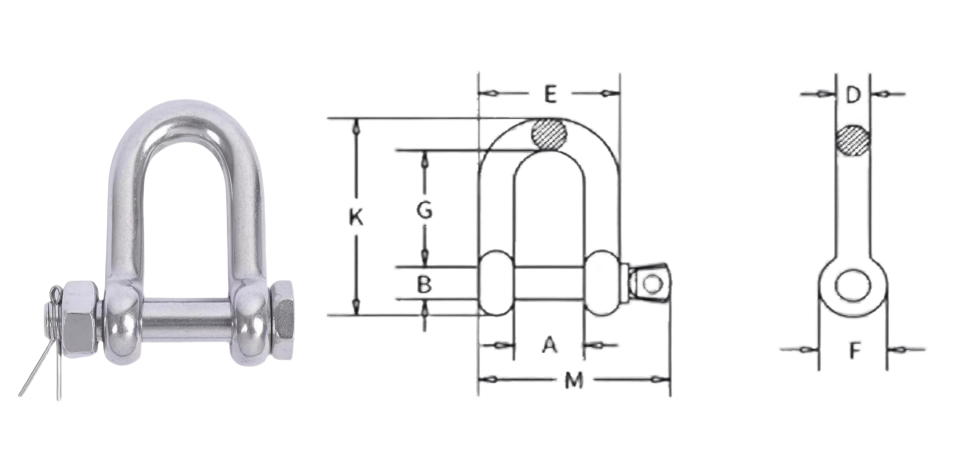

2. מבנה פשוט

ה구נה כוללת גוף בצורת האות D וציר רוחבי עם אום, מבנה פשוט, נוח להתקנה ול демונטאז', מאפשר השלמת עבודה של חיבור ופירוק במהירות, ומשפר את יעילות הפעולה

1. תחום הרמת והעמסת מטענים

כ"מוקד חיבור", הוא מחבר את קרון המניח עם חפצים כבדים שיש להרים (כגון פלדה, ציוד, מכולות) באמצעות שרשראות חבלים של חבל פלדה, מפיץ באופן שווה את עומס ההרים, מבטיח כי החפצים הכבדים לא נופלים במהלך

2.תעשיית הימי והבנייה

משמשת ליצירת ציוד על סיפון הספינה, פעולות הרמה בתשתיות ימיות (כגון פלטפורמות חופר), חיבור שרשרת עוגן וכדומה

ב סביבות לחות וקורוזיביות, הוא מקשר שרשראות עוגן, כבלים ואמצעי הרמה. דגמי פליז חלוד יכולים לעמוד בקורוזיה של מי ים, ומבטיחים את חוזק החיבור בעת קיבוע ציוד ספינות או הרמת עצמים כבדים, ומונעים שבירה הנובעת מצריכת קורוזיה.

3.הנדסה ובנייה ומכרות

הוא משמש להרים מוטות פלדה ומרכיבים ממוגזרים בבנייה, ולחבר שרשראות כרייה, ציוד הרימה (כגון חפירות, רוכבים) עם חפצים כבדים במכרות.

בהתאמה לתנאי עבודה מורכבים (כגון הרטטים והתקפי), הוא מונע רחיקת חיבור דרך מבנה נעילת המוט, מבטיח כי חומרי בניין כבדים וציוד כרייה מתחזקו באופן יציב במהלך העלאה או גררה, ומפחית תאונות תפעול.

| גודל בmm | |||||||||||

| IN | מ"מ | ת | ק"ג | א | B | G | פ | G | ק | מ | פ |

| 1\2 | 13 | 2 | 0.34 | 20.6 | 16 | 12.7 | 30.2 | 41.4 | 77 | 46 | 71.1 |

| 5\8 | 16 | 3.25 | 0.67 | 26.9 | 19.1 | 16 | 38.1 | 50.8 | 95.3 | 58.7 | 89.7 |

| 3\4 | 19 | 4.75 | 1.14 | 31.8 | 22.4 | 19.1 | 45 | 60.5 | 115.1 | 70 | 103.4 |

| 7\8 | 22 | 6.5 | 1.75 | 36.6 | 25.4 | 22.4 | 53.1 | 71.4 | 135.4 | 81 | 119.6 |

| 1 | 25 | 8.5 | 2.52 | 42.9 | 28.7 | 25.4 | 60.5 | 81 | 150.9 | 93.7 | 134.9 |

| 1-1\8 | 29 | 9.5 | 3.45 | 46 | 31.8 | 28.7 | 68.3 | 90.9 | 172.2 | 103.1 | 149.9 |

| 1-1\4 | 32 | 12 | 4.9 | 51.6 | 35.1 | 31.8 | 76.2 | 100 | 190.5 | 115.1 | 165.4 |

| 1-3\8 | 35 | 13.5 | 6.24 | 57.2 | 38.1 | 35.1 | 84.1 | 111.3 | 210.3 | 127 | 183.1 |

| 1-1\2 | 38 | 17 | 8.39 | 60.5 | 41.4 | 38.1 | 92.2 | 122.2 | 230.1 | 136.7 | 196.3 |

| 1-3\4 | 45 | 25 | 14.24 | 73.2 | 50.8 | 44.5 | 106.4 | 146.1 | 278.6 | 162.1 | 229.8 |

| 2 | 51 | 35 | 21.2 | 82.6 | 57.2 | 50.8 | 122.2 | 171.5 | 311.9 | 184.2 | 264.4 |

| 2-1\2 | 63 | 55 | 38.56 | 104.9 | 70 | 66.5 | 144.5 | 203.2 | 377 | 238.3 | 344.4 |

| כל המידות שסופקו הן תוצאות מדידה ידנית וייתכן ומכילות סטייה קלה. הממדים הסופיים יהיו בהתאם למוצר הפיזי. | |||||||||||

צוות המכירות המקצועי שלנו מחכה לייעוץ שלך.

כל הזכויות שמורות © Guanzhou Xinchuang Lianrui International Trade Co., Ltd. - מדיניותICY-בלוג