1. Robust Material

Typically made of high-quality carbon steel, through heat treatment processes such as quenching and tempering, it has high strength and hardness, capable of withstanding large tensile and shear forces.

2. Structural Design

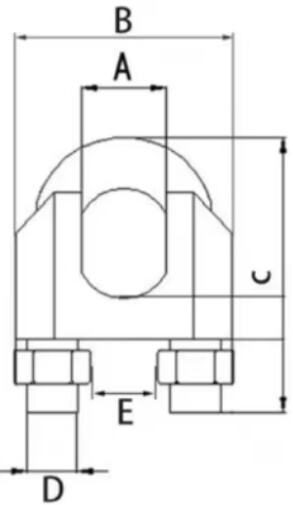

Generally composed of a U-shaped clamp ring, nuts, and washers. The opening width and arc of the U-shaped clamp ring are designed according to different specifications of steel strands to closely fit the surface of the steel strand. Nuts and washers are used to fasten the clamp ring, ensuring a secure connection.

3. Surface Treatment

To improve corrosion resistance, the surface of steel wire clamps is usually hot-dip galvanized. The zinc layer is uniform and dense, effectively preventing rusting of the steel and extending service life.

1. Simple Installation

Installation only requires placing the steel strand into the U-shaped clamp ring and tightening the nut, eliminating the need for special tools or complex procedures. This saves installation time and labor costs.

2. Reliable Connection

By tightening the nut, the U-shaped clamp ring firmly grips the steel strand, generating sufficient friction and clamping force to ensure a stable and reliable connection between the steel strand and other components, with minimal risk of loosening or slipping.

3. Strong Versatility

Available in multiple specifications, it can adapt to steel strands of different diameters and is widely used in overhead lines and structures across various industries such as power, telecommunications, and construction.

1. Steel Strand Connection

Used to connect steel strands with components such as towers, cross-arms, and insulators, allowing the steel strands to be fixed in specific positions and forming a stable overhead line structure.

2. Guy Wire Fixing

In the guy wire system of towers, it can fix the guy wire steel strand to the tower foundation or ground anchor plate, ensuring that the tension of the guy wire is effectively transmitted to the ground and stabilizing the tower.

3. Temporary Fixation

During construction or maintenance, it can be used as a temporary fixing device to secure the steel strand in place, facilitating subsequent operations such as adjusting the tension of the steel strand or installing other components.

| Clip Head Specification | A Inner width | B Total width | C Total height | D Thread diameter | Nut pitch | Nut Size | The size of the wrench opening(MM) |

| M3 | 5.6 | 18.1 | 19.2 | 3.4 | 1.8 | M4 | 7 |

| M5 | 6.1 | 21.2 | 22.9 | 4.6 | 2.9 | M5 | 8 |

| GBM6 | 8.4 | 26.7 | 32 | 5.4 | 4.5 | M6 | 10 |

| GBM8 | 11.3 | 35 | 42.1 | 7.6 | 4.4 | M8 | 14 |

| GBM10 | 12.5 | 40.7 | 48.7 | 9.5 | 4.7 | M10 | 17 |

| GBM12 | 14.4 | 48.6 | 58.4 | 11.5 | 6.2 | M12 | 19 |

| GBM15 | 18.6 | 54.1 | 68.8 | 13.4 | 9.2 | M14 | 22 |

| GBM18 | 22 | 63 | 77.2 | 15.1 | 12.9 | M16 | 24 |

| GBM20 | 21.5 | 64.5 | 82.5 | 15.1 | 13.1 | M16 | 24 |

| GBM22 | 25.8 | 73.6 | 95.5 | 17.3 | 15.1 | M18 | 27 |

| GBM25 | 29.1 | 80.8 | 103 | 19.4 | 16.6 | M20 | 30 |

| GBM28 | 31.4 | 91 | 132 | 21.5 | 21 | M22 | 32 |

| GBM32 | 35.4 | 97.2 | 152 | 23 | 23.4 | M24 | 34 |

| Non - standardM6 | 8.9 | 27.4 | 30 | 5.3 | 4.5 | M6 | 10 |

| Non - standardM8 | 9.6 | 32.1 | 36.6 | 6.9 | 3.1 | M8 | 13 |

| Non - standardM10 | 11.2 | 34.8 | 41.5 | 7.4 | 5 | M8 | 14 |

| Non - standardM12 | 13.6 | 44.9 | 55 | 9 | 5.2 | M10 | 17 |

| Non - standardM15 | 17.2 | 50.4 | 62.3 | 11.2 | 8.3 | M12 | 19 |

| Non - standardM18 | 22.3 | 59.6 | 75.1 | 12.6 | 13.4 | M14 | 22 |

| All measurements provided are manually obtained and may contain slight tolerances. Final dimensions shall be subject to the physical product. | |||||||

Our professional sales team are waiting for your consultation.