1. Convenient and Efficient Installation

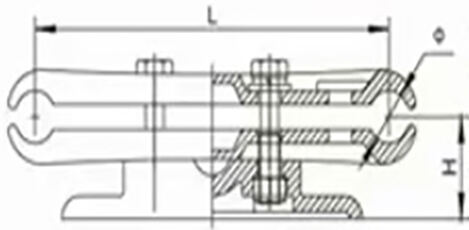

Adopts a modular design, directly docked with post insulators through connecting plates (e.g., four-hole M12 bolt installation), which can be assembled without complex tools, improving construction efficiency by over 30%.

The pre-twisted wire or lead screw adjustment structure further simplifies the spacing adjustment process, especially suitable for aerial work scenarios.

2. Life Cycle Economy

The corrosion resistance of aluminum alloy material and the non-destructive fixing technology of pre-twisted wires can extend the service life of the fitting and flexible busbar (designed service life ≥30 years), reducing replacement frequency and maintenance costs.

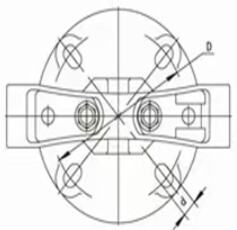

Meanwhile, the adjustable spacing function allows the same model of fitting to adapt to multiple specifications of conductors, reducing the inventory pressure of spare parts.

3. Optimized Electrical and Mechanical Performance

By accurately maintaining the spacing of double-split busbars, it ensures uniform electric field distribution, reduces surface potential gradients, and avoids power loss and equipment aging caused by corona discharge.

Under short-circuit conditions, the stable structure can resist the mutual attraction of busbars caused by electromagnetic forces and prevent collision damage.

4. Compatibility and Versatility

Suitable for various flexible busbar types such as aluminum stranded wires and steel-core aluminum stranded wires, and can be used with tension insulator strings, spacers, and other fittings to form a complete busbar fixing system.

Substations of different voltage levels (e.g., 220kV, 500kV) can select MSG models with corresponding spacing specifications as needed.

E-mail:

E-mail: