1. Convenient Installation

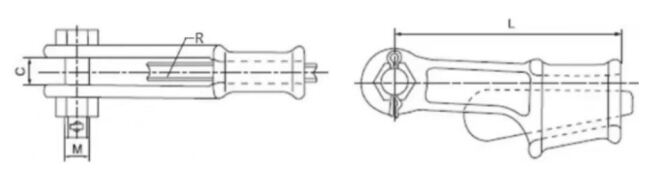

The installation process is simple: just bend the steel strand as required and place it into the clamp, requiring no complex tools or procedures. Once installed, it is secure and unlikely to loosen.

2. Excellent Self-Locking Performance

Features a strong self-locking function: as the tension on the steel strand increases, the friction between the wedge and the strand also increases, ensuring a firm clamping effect and high safety.

3. Wide Application Range

Can be used for installing steel strands, fastening overhead ground wires, and securing guy wires on guyed towers. It is also commonly used with UT-type clamps to fix conductors or overhead ground wires to the tension insulator strings of non-straight towers.

E-mail:

E-mail: