1. Tough Materials

Typically made of high-quality carbon steel or high-strength aluminum alloy. High-quality carbon steel offers high strength and toughness, capable of withstanding large tensile forces; aluminum alloy is lightweight and corrosion-resistant. Both materials are generally hot-dip galvanized or undergo other anti-corrosion treatments to adapt to complex outdoor environments.

2. Structural Design

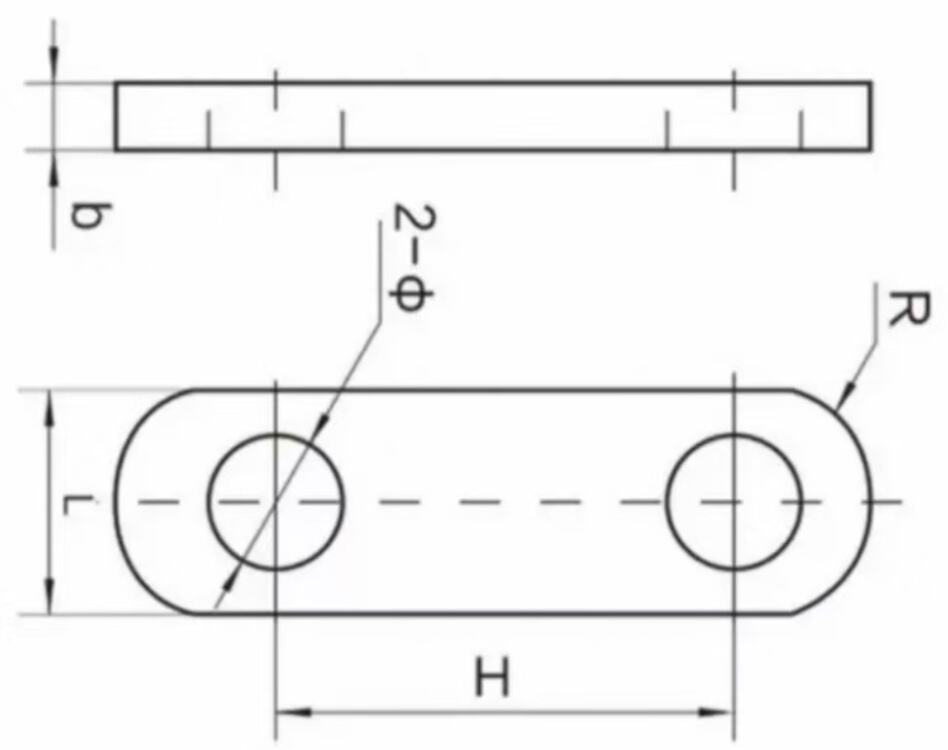

Shaped as a flat plate with multiple bolt holes along the length direction. The inner walls of the bolt holes may be coated with composite coatings to improve wear and corrosion resistance. The size and spacing of the connection holes at both ends are designed according to standards, facilitating connection with other fittings.

1. Reliable Connection

Connected to other fittings via bolts or pins, ensuring a tight joint that reduces resistance and energy loss at the connection point. It remains secure after long-term use, guaranteeing stable operation of power lines.

2. Adjustable Length

Equipped with multiple bolt holes, allowing users to adjust the connection length by selecting different hole positions. This expands the adjustment range, enabling adaptation to fittings or lines with varying spacing requirements and enhancing versatility.

3. Strong Versatility

Available in various specifications and models, it can be used with multiple types of insulators, suspension rings, clamps, and other fittings. It is suitable for overhead power lines and substations across all voltage classes.

1. Fitting Connection

As a critical component for connecting various fittings, it links insulator strings, tension clamps, suspension clamps, and other fittings to form a complete power transmission system, ensuring both the electrical and mechanical performance of the line.

2. Length Adjustment

In power lines, it is used to adjust the length of insulator strings or fitting strings. By fixing at different hole positions, it dynamically adjusts the fitting length and controls conductor tension, ensuring uniform force distribution across components and enhancing line stability and safety.

3. Adaptation to Working Condition Changes

It can adapt to the expansion and contraction of conductors caused by factors such as temperature and ice/snow. By adjusting its own length, the line maintains optimal operation under different working conditions, reducing faults like insulator tilting or conductor breakage and power outages caused by uneven tension.

| Model | ALL SIZE(MM) | Nominal breaking load(KN) | Weight(kg) | ||||

| Φ | H | b | L | R | |||

| PD-7 | 18 | 70 | 16 | 40 | 22 | 70 | 0.57 |

| PD-10 | 20 | 80 | 16 | 45 | 24 | 100 | 0.86 |

| PD-12 | 24 | 100 | 16 | 50 | 26 | 120 | 1.05 |

| PD-16 | 26 | 100 | 18 | 60 | 32 | 160 | 1.28 |

| PD-20 | 30 | 120 | 26 | 72 | 36 | 200 | 2.50 |

| All measurements provided are manually obtained and may contain slight tolerances. Final dimensions shall be subject to the physical product | |||||||

Our professional sales team are waiting for your consultation.