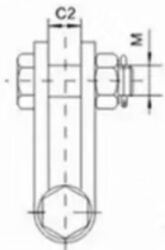

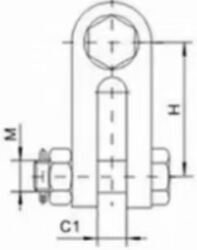

1. Secure Connection

Fastened to towers, insulator strings, etc., using high-strength bolts or other specialized connecting accessories, ensuring a tight and corrosion-resistant joint that can operate stably for long periods in harsh outdoor environments.

2. Flexible Redirection

With its right-angle connection orientation, it offers flexible redirection and strong adaptability, capable of changing connection directions as needed to effectively transmit electrical loads.

3. Maintenance-Friendly

Easy to install and disassemble. During line inspections, insulator replacement, and other maintenance tasks, workers can use the connection points of the right-angle hanging plate to easily hang repair tools or temporarily secure equipment. Its stable structure can bear a certain weight, ensuring safe and orderly maintenance operations.

E-mail:

E-mail: