1. Tuning - fork - type Structure

It adopts a special tuning - fork - type structure. There are hammer heads of different masses at both ends of the steel strand, and the distances from the suspension point to the two ends are unequal, which can produce four resonant audio frequencies. The frequency coverage range is 6Hz - 150Hz, which can well cover the vibration frequency range of conductors and ground wires.

2. High - quality Materials

It is generally composed of galvanized cast - iron hammer heads, hot - dip galvanized steel strands, aluminum - alloy clamps, stainless - steel bolts, etc. The hammer heads are made of U - shaped pig iron, with excellent anti - fatigue performance, capable of withstanding long - term vibration and impact. The surface has undergone special anti - corrosion treatment, with strong anti - corrosion properties, and can adapt to harsh outdoor environments.

3. Unique Design

It adopts the typical Haro design, whose basic principle is dynamic energy absorption. The unique appearance design prevents ice and water accumulation, and the anti - corona design is adopted to prevent corona occurrence.

1. Excellent Vibration Damping Performance

It effectively controls aeolian vibrations of various intensities, significantly reducing the amplitude of conductors and ground wires while minimizing the frequency range of stable vibrations. By eliminating conductor fatigue, it ensures the service life of conductors, ground wires, and OPGW (Optical Ground Wire) of various models.

2. Convenient Installation

Some models use preformed strand installation, requiring no tools, which ensures construction safety and eliminates human error. This innovative design completely solves the long-standing problem of shock absorber slippage, as the preformed strands provide a self-locking grip that maintains secure positioning without additional fasteners. The tool-free installation also reduces high-altitude operation risks and accelerates project completion.

3. Strong Adaptability

Capable of withstanding diverse meteorological conditions and line environments, It is suitable for overhead transmission lines across multiple voltage classes. Its versatile design makes it ideal for complex terrains and special applications.

1. Vibration Elimination

Installed on overhead lines, when the conductor vibrates due to wind or other factors, the shock absorber moves up and down. The inertia of the heavy hammer induces internal friction in the steel strand, dissipating the conductor's vibrational energy. Meanwhile, air damping on the hammer and energy dissipation/reflection at the clamp further reduce or even eliminate conductor amplitude. This protects the conductor, fittings, and insulators from vibration-induced damage by breaking the energy chain of sustained oscillations.

2. Line Protection

By effectively suppressing line vibrations, it reduces the risk of fatigue damage caused by repeated bending of the conductor at suspension points, extending the line’s service life. This results in lower maintenance costs and fewer power outages due to vibration-related failures. The shock absorber’s dual role in energy dissipation and stress reduction ensures the long-term integrity of overhead systems, particularly in high-vibration environments like long-span crossings or turbulent wind zones.

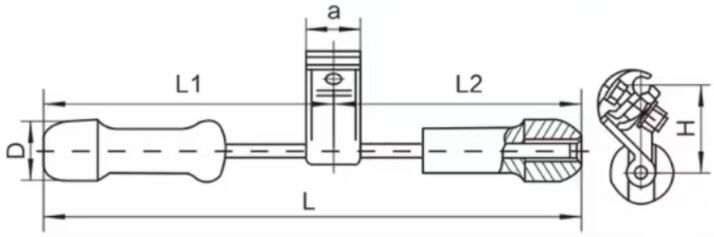

| Model | Applicable conductor diameter(MM) | ALL SIZE(MM) | Weight(KG) | ||

| L | H | a | |||

| FRY-1/G | 6.4~8.6 | 280 | 45 | 40 | 1.5 |

| FRY-2/G | 8.6~12.0 | 380 | 60 | 50 | 2.2 |

| FRY-3/G | 12.0~14.5 | 480 | 65 | 60 | 4.2 |

| FRY-1/2 | 12.0~16.0 | 429 | 80 | 50 | 2.8 |

| FRY-2 | 12.0~16.0 | 429 | 80 | 50 | 2.8 |

| FRY-2/3 | 16.0~18.0 | 429 | 80 | 50 | 2.8 |

| FRY-3/4 | 18.0~22.5 | 505 | 90 | 60 | 4.5 |

| FRY-3/5 | 22.5~30.0 | 505 | 90 | 60 | 5.0 |

| FRY-4/5 | 22.5~30.0 | 550 | 97 | 60 | 7.6 |

| FRY-4/6 | 30.0~35.0 | 550 | 97 | 60 | 7.6 |

| All measurements provided are manually obtained and may contain slight tolerances. Final dimensions shall be subject to the physical product. | |||||

Our professional sales team are waiting for your consultation.