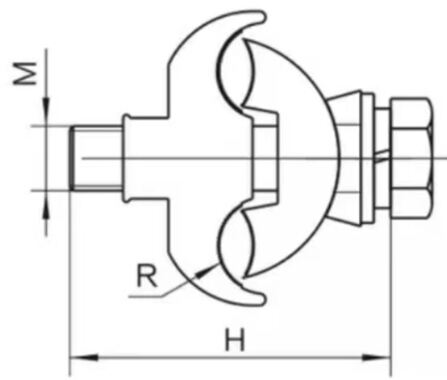

1. Low Contact Resistance

The toothed structure and large contact area ensure a tight fit between the clamp and the conductor, effectively reducing contact resistance and minimizing power loss and heat generation.

2. Reliable Connection

With strong clamping force and low contact resistance, it achieves reliable electrical and mechanical connections between aluminum conductors, ensuring stable power transmission.

3. Convenient Installation

The integrated components and common bolt-fastening design simplify the installation process, improving construction efficiency and reducing installation difficulty.

4. Excellent Insulation Performance

Can be used with an insulation cover. The insulation cover has a power-frequency withstand voltage of ≥18kV without breakdown after 1 minute of pressure holding, and an insulation resistance >1.0×10¹⁴Ω, providing effective insulation protection.

5. Strong Weather Resistance

The aluminum alloy material combined with good surface treatment can withstand UV radiation, rain erosion, etc., maintaining stable performance in environments ranging from -30°C to 90°C. It performs well after 1,008 hours of artificial weathering aging tests.

E-mail:

E-mail: