FD-001-3

1. Prosta konstrukcja

Zazwyczaj składa się z głowicy młota, stalowego sznura i zacisku, posiada skrośną prostą strukturę, co ułatwia instalację i konserwację. Projekt modułowy umożliwia szybkie wymienianie poszczególnych komponentów (np. głowicy lub sznura) bez użycia specjalistycznego narzędzi, zmniejszając przestoje podczas konserwacji.

2. Racjonalny rozkład masy

Głowica młotka jest zazwyczaj wykonana z żeliwa lub innych materiałów o dużej gęstości, zapewniając znaczną masę. Połączona ze złączem za pomocą stalowego sznura, ten projekt zapewnia racjonalny rozkład masy, umożliwiając amortyzatorowi skuteczne pochłanianie i rozpraszanie energii wibracyjnej z przewodnika. Inercja ciężkiej głowicy młotka przeciwstawia się oscylacjom przewodnika, minimalizując amplitudę oraz naprężenia zmęczeniowe.

3. Dobra dopasowalność częstotliwościowa

Poprzez dostosowanie parametrów takich jak długość stalowego sznura czy masa głowicy młotka, można ją dostroić do odpowiednich własnych częstotliwości drgań, co czyni ją dobrze przystosowaną do tłumienia wibracji przewodników w wielu zakresach częstotliwości. Ta elastyczność umożliwia jej zastosowanie do różnych specyfikacji przewodników (np. pole przekroju, napięcie) oraz warunków eksploatacji linii (np. prędkość wiatru, ukształtowanie terenu), zapewniając optymalną skuteczność tłumienia wibracji w różnych warunkach.

1. Duża uniwersalność

Dostępny w różnych specyfikacjach i modelach, nadaje się do przewodów napowietrznych o różnych przekrojach i materiałach, w tym kabli aluminiowych ze stalowym wzmacnianiem (ACSR), kabli aluminiowych wielożyłowych itp. Znajduje szerokie zastosowanie w liniach transmisyjnych o różnych klasach napięcia (np. 10 kV do 500 kV), wykazując dużą adaptowalność do różnych struktur sieciowych i warunków środowiskowych.

2. Wysoka niezawodność

Weryfikowany w długotrwałej praktyce inżynierskiej, tłumik drgań FD charakteryzuje się stabilną konstrukcją i właściwościami, utrzymując doskonały efekt tłumienia drgań podczas długotrwałej pracy na zewnątrz. Efektywnie zmniejsza uszkodzenia zmęczeniowe przewodów spowodowane drganiami, znacznie poprawiając niezawodność pracy linii. Jego udowodniona trwałość w trudnych warunkach środowiskowych (np. silny wiatr, duże oblodzenie) czyni go zaufanym wyborem dla przedsiębiorstw energetycznych na całym świecie.

1. Tłumienie drgań przewodów

Montowany na przewodach jezdnych, gdy przewód drga pod wpływem wiatru lub innych czynników, tłumik tłumi energię drgań przewodu poprzez własne oscylacje, zmniejszając amplitudę drgań przewodu. Zapobiega to pękaniu drutu spowodowanemu zmęczeniem oraz zużyciu armatury linii wynikłemu z długotrwałych drgań, dzięki czemu utrzymywana jest integralność mechaniczna linii transmisyjnej.

2. Ochrona urządzeń linii

Efektywne tłumienie drgań przewodów pozwala chronić nie tylko same przewody, ale także połączone z nimi urządzenia linii, takie jak armatura i izolatory, przedłużając ich czas eksploatacji. To zmniejsza nakłady pracy konserwacyjnej i koszty utrzymania linii, a jednocześnie zapewnia bezpieczną i stabilną pracę systemu transmisji. Mechanizm rozpraszania energii tłumika minimalizuje naprężenia działające na kluczowe komponenty, co czyni go niezbędnym elementem zapobiegającym przedwczesnemu uszkodzeniu linii napowietrznych.

| Model | Zastosowanie do przekroju drutu skręcanego (MM2) | Schemat | Wszystkie rozmiary (mm) | Specyfikacja stalowego drutu skręcanego | Waga(kg) | |||||

| Stalowa żyła | Aluminiowy przewód skręcony, ACSR | G | A | H | L1 | L | ||||

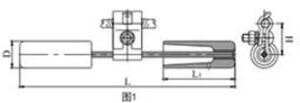

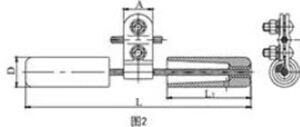

| FD-1 | / | 35~50 | Rysunek2 | 40 | 40 | 40 | 95 | 300 | 7/2.6 | 1.35 |

| FD-2 | / | 70~95 | Rysunek1 | 46 | 45 | 55 | 130 | 370 | 7/3.0 | 2.4 |

| FD-3 | / | 120~150 | Rysunek1 | 56 | 60 | 65 | 150 | 450 | 19/2.2 | 4.5 |

| FD-4 | / | 185~240 | Rysunek1 | 62 | 60 | 68 | 175 | 500 | 19/2.2 | 5.6 |

| FD-5 | / | 300~500 | Rysunek1 | 67 | 70 | 73 | 200 | 550 | 19/2.6 | 7.2 |

| FD-6 | / | 500~630 | Rysunek1 | 70 | 70 | 78 | 200 | 550 | 19/2.6 | 8.6 |

| FG-35 | 35 | / | Rysunek2 | 42 | 45 | 50 | 100 | 300 | 7/3.0 | 1.8 |

| FG-50 | 50 | / | Rysunek2 | 46 | 45 | 50 | 130 | 350 | 7/3.0 | 2.4 |

| FG-70 | 70 | / | Rysunek1 | 56 | 50 | 60 | 150 | 400 | 19/2.2 | 4.2 |

| FG-100 | 100 | / | Rysunek1 | 62 | 60 | 65 | 175 | 500 | 19/2.2 | 5.9 |

| Wszystkie podane wymiary zostały zmierzone ręcznie i mogą zawierać niewielkie tolerancje. Ostateczne wymiary będą zależne od produktu fizycznego. | ||||||||||

Nasz profesjonalny zespół sprzedaży czeka na Twoje zapytanie.

Prawa autorskie © GuangZhou XinChuang LianRui International Trade Co., Ltd. Wszelkie prawa zastrzeżone. - Polityka prywatności- Nie.Blog