1. Simple Structure

Typically composed of a hammer head, steel strand, and clamp, it has a concise overall structure that facilitates installation and maintenance. The modular design allows for quick replacement of individual components (e.g., hammer head or strand) without specialized tools, reducing downtime during maintenance.

2. Rational Mass Distribution

The hammer head is generally made of cast iron or other high-density materials, providing substantial mass. Connected to the clamp via a steel strand, this design ensures rational mass distribution, enabling the shock absorber to effectively absorb and dissipate vibrational energy from the conductor. The inertia of the heavy hammer head counteracts conductor oscillations, minimizing amplitude and fatigue stress.

3. Good Frequency Adaptability

By adjusting parameters such as steel strand length and hammer head mass, it can be tuned to have appropriate natural vibration frequencies, making it well-suited for suppressing conductor vibrations across multiple frequency ranges. This adaptability allows it to cater to different conductor specifications (e.g., cross-sectional area, tension) and line operating environments (e.g., wind speed, terrain), ensuring optimal vibration damping performance in various scenarios.

1. Strong Versatility

Available in various specifications and models, it is suitable for overhead conductors of different cross-sections and materials, including aluminum-conductor steel-reinforced (ACSR) cables, aluminum stranded cables, etc. It finds wide application in transmission lines of different voltage classes (e.g., 10kV to 500kV), demonstrating strong adaptability to diverse grid structures and environmental conditions.

2. High Reliability

Verified through long-term engineering practice, the FD shock absorber features stable structure and performance, maintaining excellent vibration-damping effects during prolonged outdoor operation. It effectively reduces fatigue damage to conductors caused by vibration, significantly improving the reliability of line operation. Its proven durability in harsh environments (e.g., high wind, heavy icing) makes it a trusted choice for power utilities worldwide.

1. Conductor Vibration Damping

Installed on overhead conductors, when the conductor vibrates due to wind or other factors, the shock absorber dissipates the conductor's vibrational energy through its own oscillations, reducing the amplitude of conductor vibration. This prevents fatigue-induced strand breakage in the conductor and wear of line fittings caused by long-term vibration, thereby maintaining the mechanical integrity of the transmission line.

2. Protection of Line Equipment

By effectively suppressing conductor vibration, it protects the conductor itself as well as connected line equipment such as fittings and insulators, extending their service life. This reduces maintenance workload and costs for the line, while ensuring the safe and stable operation of the transmission system. The shock absorber's energy-dissipating mechanism minimizes stress on critical components, making it an essential component for preventing premature failure in overhead lines.

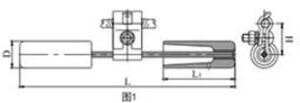

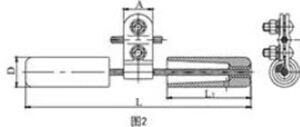

| Model | Applicable twisted wire section(MM2) | Diagram | ALL SIZE(MM) | Specification of steel twisted wire | Weight(KG) | |||||

| Steel Grain Line | Aluminum stranded wire, ACSR | D | A | H | L1 | L | ||||

| FD-1 | / | 35~50 | Figure2 | 40 | 40 | 40 | 95 | 300 | 7/2.6 | 1.35 |

| FD-2 | / | 70~95 | Figure1 | 46 | 45 | 55 | 130 | 370 | 7/3.0 | 2.4 |

| FD-3 | / | 120~150 | Figure1 | 56 | 60 | 65 | 150 | 450 | 19/2.2 | 4.5 |

| FD-4 | / | 185~240 | Figure1 | 62 | 60 | 68 | 175 | 500 | 19/2.2 | 5.6 |

| FD-5 | / | 300~500 | Figure1 | 67 | 70 | 73 | 200 | 550 | 19/2.6 | 7.2 |

| FD-6 | / | 500~630 | Figure1 | 70 | 70 | 78 | 200 | 550 | 19/2.6 | 8.6 |

| FG-35 | 35 | / | Figure2 | 42 | 45 | 50 | 100 | 300 | 7/3.0 | 1.8 |

| FG-50 | 50 | / | Figure2 | 46 | 45 | 50 | 130 | 350 | 7/3.0 | 2.4 |

| FG-70 | 70 | / | Figure1 | 56 | 50 | 60 | 150 | 400 | 19/2.2 | 4.2 |

| FG-100 | 100 | / | Figure1 | 62 | 60 | 65 | 175 | 500 | 19/2.2 | 5.9 |

| All measurements provided are manually obtained and may contain slight tolerances. Final dimensions shall be subject to the physical product. | ||||||||||

Our professional sales team are waiting for your consultation.