1. Unique Structure

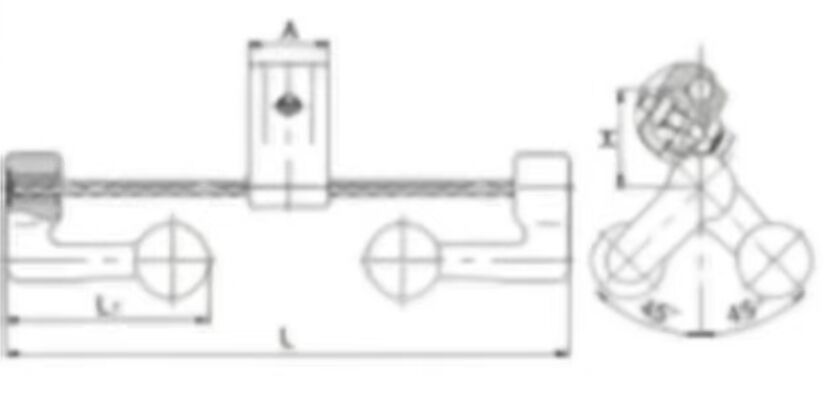

The hammer heads are shaped like eccentric eggplants and installed opposite each other on the steel strands at both ends of the clamp. A pre-torque is generated as the hammer heads form a 60° angle with the clamp, which is why it is also called a torque shock absorber. This innovative design enhances energy dissipation by utilizing both translational and torsional vibrations, providing superior damping performance compared to traditional linear dampers.

2. Excellent Frequency Characteristics

It can achieve three natural vibration frequencies, offering a wide frequency coverage range that effectively adapts to different conductor vibration conditions. This multi-frequency capability allows it to suppress conductor vibrations across various wind-induced frequencies, making it suitable for complex meteorological environments and multi-span line structures.

3. Material Composition

Typically composed of galvanized cast iron hammer heads, hot-dip galvanized steel strands, aluminum alloy clamps, and stainless steel bolts, it combines high strength, toughness, and corrosion resistance。

E-mail:

E-mail: