XTS-001-4

1. Specjalny skład materiału

Niektóre typy są produkowane z użyciem taśmy kompozytowej miedziowo-aluminiowej o sile połączenia miedź-aluminium ≥100MPa. To rozwiązanie łączy doskonałą przewodność elektryczną miedzi z lekką oraz odpornością na korozję aluminium, co czyni ją idealną do zastosowań w warunkach przesyłania dużego prądu, jednocześnie zmniejszając wagę konstrukcji i poprawiając odporność środowiskową.

2. Projekt strukturalny

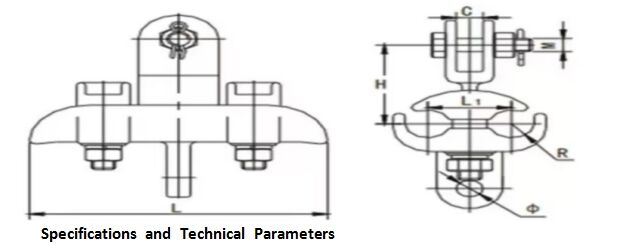

Zazwyczaj składa się z płyty nośnej przewodnika, bloku dociskowego, zespołu zawieszenia oraz elementów mocujących:

Płyta nośna przewodnika i blok dociskowy posiadają dwa rowki pod przewody, oddzielone płaską powierzchnią i otworami prześwietlającymi.

Przewody są umocowane za pomocą elementów mocujących przechodzących przez otwory, zapewniając pewne zaciskanie.

Zespół zawieszenia jest centralnie umieszczony na płaskiej powierzchni między dwiema rowkami drutowymi płyty nośnej, zapewniając zrównoważone wsparcie mechaniczne i precyzyjne wyrównanie do instalacji napowietrznej.

3. Niskie opory i generowanie ciepła

Na przykład zacisk zawieszeniowy XTS wykorzystujący taśmy kompozytowe miedziowo-aluminiowe wykazuje niższe opory elektryczne i generowanie ciepła w porównaniu do tradycyjnych stopów aluminium lub produktów ferromagnetycznych. To zmniejsza straty energii podczas transmisji – testy wykazały 15-20% redukcję rozpraszania energii przy obciążeniu znamionowym – co poprawia efektywność transmisji i minimalizuje naprężenia termiczne działające na przewody i urządzenia

1. Doskonała skuteczność oszczędzania energii

Dzięki niskiemu oporowi elektrycznemu i charakterystyce generowania ciepła zmniejsza ono zużycie energii w liniach przesyłowych, osiągając oszczędność energii i ochronę środowiska. Jest to szczególnie odpowiednie do scenariuszy przesyłu z surowymi wymaganiami dotyczącymi strat mocy, takimi jak linie napowietrzne wysokiego i bardzo wysokiego napięcia, gdzie można znacząco poprawić ogólną skuteczność systemu.

2. Wygodna instalacja

Dzięki racjonalnemu projektowi konstrukcyjnemu proces instalacji jest stosunkowo prosty, nie wymaga skomplikowanych narzędzi ani specjalnych umiejętności. Personel budowlany może szybko wykonać montaż, skutecznie skracając czas realizacji inwestycji i zwiększając wydajność pracy. Ta cecha jest bardzo korzystna zarówno dla nowych projektów sieci energetycznej, jak i prac serwisowych, minimalizując koszty pracy i opóźnienia projektowe.

3. Szeroki zakres zastosowań

Jako rodzaj złączki liniowej jest powszechnie stosowany do mocowania jumpersów dwuprzewodowych w liniach napowietrznych. Nadaje się do linii przesyłowych napowietrznych o różnych klasach napięcia, co pokazuje dużą adaptowalność do różnych struktur sieci. Jego uniwersalność czyni go idealnym wyborem dla miejskich sieci energetycznych, linii rozdzielczych wiejskich oraz projektów przesyłowych na duże odległości.

1. Mocowanie jumpersa

Głównie stosowany w liniach napowietrznych do mocowania jumpersów dwuprzewodowych do łańcuchów izolatorów lub słupów/wież energetycznych, zapewniając, że jumpersy zachowują określone położenie i kształt. Spełnia wymagania montażowe i eksploatacyjne urządzeń elektrycznych, zapobiegając ich przemieszczaniu się i gwarantując odpowiednie odstępy potrzebne do bezpiecznej transmisji energii elektrycznej.

2. Przenoszenie obciążenia

Ponosi siłę grawitacyjną skoków, obciążenie wiatrem oraz inne obciążenia środowiskowe, przekazując te siły na słupy/wieże energetyczne lub łańcuchy izolatorów. Zaprojektowane tak, aby wytrzymać różne warunki meteorologiczne, zapewnia bezpieczne zawieszenie jumpers (skoków) i utrzymuje stabilność mechaniczną systemu linii napowietrznej.

3. Połączenie elektryczne

Dzięki zoptymalizowanemu projektowi styku zapewnia doskonałą przewodność elektryczną między jumperami a innym sprzętem elektrycznym, minimalizując opór kontaktowy. To zmniejsza generowanie ciepła oraz problemy z wyładowaniami spowodowanymi słabymi połączeniami, gwarantuje płynny przepływ energii i spełnia normy wysokiego napięcia dotyczące izolacji oraz przewodności.

| Model SG | Model równoważny | Zakres średnic przewodnika (w tym średnica skrętki) | Wielkość ((mm) | Maksymalna nośność (kN) | |||||

| φ | R | L | M | C | H | ||||

| XTS-4028 | XTS-2B | 18 | 14 | 200 | 16 | 20 | 77 | 40 | |

| XTS-4034 | XTS-2 | 18 | 17 | 200 | 16 | 20 | 81 | 40 | |

| XTS-2C | 18 | 20 | 250 | 16 | 20 | 103 | 40 | ||

| XTS-6022 | 18 | 13 | 200 | 16 | 20 | 77 | 60 | ||

| XTS-6028 | 22.0~27.0 | 18 | 14 | 200 | 16 | 20 | 77 | 60 | |

| XTS-6034 | XTS-5 | 27.0~33.0 | 18 | 17 | 200 | 16 | 20 | 81 | 60 |

| XTS-6040 | 32.0~39.0 | 18 | 20 | 250 | 16 | 20 | 103 | 60 | |

| XTS-6 | 34.0~45.0 | 18 | 23 | 250 | 16 | 20 | 103 | 70 | |

| Wszystkie podane wymiary zostały zmierzone ręcznie i mogą zawierać niewielkie tolerancje. Ostateczne wymiary należy dostosować do produktu fizycznego | |||||||||

Nasz profesjonalny zespół sprzedaży czeka na Twoje zapytanie.

Prawa autorskie © GuangZhou XinChuang LianRui International Trade Co., Ltd. Wszelkie prawa zastrzeżone. - Polityka prywatności- Nie.Blog