MSG-001-1

1. Adjustable Spacing Structure

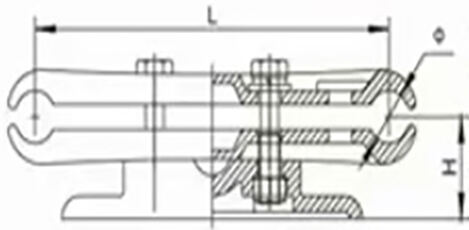

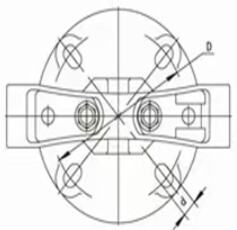

Adopts a dual-plate linkage design, with sliding coordination between T-shaped guide rails and moving blocks to precisely adjust the spacing of double-split flexible busbars (e.g., standard specifications such as 120mm, 200mm, 400mm), adapting to different engineering requirements.

This adjustment function solves the problem that traditional fixed fittings cannot flexibly adapt to busbar spacing, avoiding degraded electrical performance or mechanical stress concentration caused by spacing deviations.

2. Lightweight and High-Strength Material

The main body is made of aluminum alloy, which is lightweight (approximately 40% lighter than traditional steel fittings) and high-strength, both reducing the overall load of flexible busbars and meeting mechanical stress requirements during long-term operation.

The aluminum alloy material also has excellent corrosion resistance, adapting to harsh environments such as acid rain and salt spray, and reducing maintenance frequency.

3. Combination of Pre-Twisted Wire and Mechanical Fastening

Some models use pre-twisted wire winding for fixing, featuring a large contact area and uniform adhesion distribution to avoid local conductor damage caused by traditional bolt fastening.

Meanwhile, busbar clamping is achieved through lead screw transmission or hexagonal adjustment structures, ensuring no risk of slippage after installation and improving connection reliability.

4. Low Hysteresis and Anti-Corona Design

The non-magnetic properties of aluminum alloy eliminate hysteresis loss and reduce power consumption.

The surface of the fitting is smooth-treated or coated with an anti-corona layer to minimize tip discharge, meeting insulation requirements in high-voltage transmission environments.

1. Convenient and Efficient Installation

Adopts a modular design, directly docked with post insulators through connecting plates (e.g., four-hole M12 bolt installation), which can be assembled without complex tools, improving construction efficiency by over 30%.

The pre-twisted wire or lead screw adjustment structure further simplifies the spacing adjustment process, especially suitable for aerial work scenarios.

2. Life Cycle Economy

The corrosion resistance of aluminum alloy material and the non-destructive fixing technology of pre-twisted wires can extend the service life of the fitting and flexible busbar (designed service life ≥30 years), reducing replacement frequency and maintenance costs.

Meanwhile, the adjustable spacing function allows the same model of fitting to adapt to multiple specifications of conductors, reducing the inventory pressure of spare parts.

3. Optimized Electrical and Mechanical Performance

By accurately maintaining the spacing of double-split busbars, it ensures uniform electric field distribution, reduces surface potential gradients, and avoids power loss and equipment aging caused by corona discharge.

Under short-circuit conditions, the stable structure can resist the mutual attraction of busbars caused by electromagnetic forces and prevent collision damage.

4. Compatibility and Versatility

Suitable for various flexible busbar types such as aluminum stranded wires and steel-core aluminum stranded wires, and can be used with tension insulator strings, spacers, and other fittings to form a complete busbar fixing system.

Substations of different voltage levels (e.g., 220kV, 500kV) can select MSG models with corresponding spacing specifications as needed.

1. Mechanical Fixing of Flexible Busbars

Through the combination of tension clamps and connecting plates, double-split flexible busbars are reliably fixed to post insulators, bearing the self-weight of the busbars, wind loads, and short-circuit electrodynamic forces to ensure the structural stability of the line. Especially in long-span busbar arrangements, its adjustment function can compensate for spacing changes caused by thermal expansion and contraction.

2. Standardized Maintenance of Split Spacing

Strictly maintains the preset spacing of double-split busbars (e.g., 120mm, 200mm), meeting the requirements of electrical design for phase-to-phase distances, avoiding the risk of phase-to-phase flashover caused by reduced spacing, and optimizing the electric field distribution around the busbars to reduce corona loss.

3. Assisted Line Maintenance and Overhaul

During installation or maintenance, it can be used as a temporary fixing point to assist in busbar positioning, facilitating worker operations; the adjustment function can also flexibly adapt to new spacing requirements when replacing busbars or adjusting layouts, reducing construction difficulties.

4. Synergy with Other Fittings

When used in conjunction with busbar spacers, grading rings, and other fittings, it forms a multi-layer protection system: spacers suppress vibrations, grading rings optimize the electric field, while MSG fittings provide basic mechanical fixing and spacing assurance, jointly improving the reliability and safety of transmission lines.

| Model | ACS of Busbars(MM) | ALL SIZE(MM) | |||||

| Φ | M | L | D | d | |||

| MSG-4/120 | 185~240 | 23 | 44 | 120 | 140 | 14 | |

| MSG-5/120 | 300~400 | 30 | 47 | 120 | |||

| MSG-6/120 | 500~630 | 36 | 53 | 120 | |||

| MSG-4/200 | 185~240 | 23 | 44 | 200 | |||

| MSG-5/200 | 300~400 | 30 | 47 | 200 | |||

| MSG-6/200 | 500~630 | 36 | 53 | 200 | |||

| MSG-4/400 | 185~240 | 23 | 44 | 400 | |||

| MSG-5/400 | 300~400 | 30 | 47 | 400 | |||

| MSG-6/400 | 500~630 | 36 | 53 | 400 | |||

| MSG-4/120-225 | 185-240 | 23 | 44 | 120 | 225 | 18 | |

| MSG-5/120-225 | 300~400 | 30 | 47 | 120 | |||

| MSG-6/120-225 | 500~630 | 36 | 53 | 120 | |||

| MSG-4/200-225 | 185~240 | 23 | 44 | 200 | |||

| MSG-5/200/225 | 300~400 | 30 | 47 | 200 | |||

| MSG-6/200-255 | 500~630 | 36 | 53 | 200 | |||

| MSG-4/400-225 | 185~240 | 23 | 44 | 400 | |||

| MSG-5/400-225 | 300~400 | 30 | 47 | 400 | |||

| MSG-6/400-225 | 500~630 | 36 | 53 | 400 | |||

| All measurements provided are manually obtained and may contain slight tolerances. Final dimensions shall be subject to the physical product. | |||||||

Note:

1. The main body is made of aluminum alloy parts, and the rest are hot-dip galvanized steel parts.

2.If the hole spacing of the supporting post insulators required by the user is different from the above, please specify when placing an order.

Our professional sales team are waiting for your consultation.

Copyright © GuangZhou XinChuang LianRui International Trade Co., Ltd. All Rights Reserved. - Privacy policy - Blog